Well, I didn't get to do much during the Christmas break, but New Year's Eve was productive.

Today I was able to get the t-molding on... what a pain. But it does look nice. t-molding.com was able to get me two matching rolls of Galaxian Green (the previous 2 rolls sent to me were slightly different) and I lucked out in that they are almost an exact paint match to the sides.

I also got the GGG LED bar installed and it is BRIGHT! My only complaint is the 3" of wire they give you and it's very thin gauge... but I can work with it. I had a 12V harness from another project (8 AA batteries) that I was able to hook up to it and test it out with the marquee in place.

Tomorrow, weather/wife permitting, I plan on getting the Luminglas mounted in the front hole, wire up the speakers, mount the marquee (picked up the L-shaped molding from Home Depot and need to spray paint black), and mount the SmartStrip inside the cab.

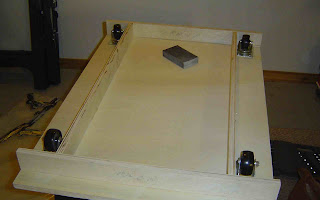

I'm debating working on the bezel first or jumping straight to the CP. I have to admit the CP has me a little frazzled as I'm not good with electronics or drilling straight/vertical holes. That said, if I ever want to play this thing, I'm going to have to do it sooner or later...

Happy New Year, all!

Jim